EPDM Roofing Installation

At Superior Roofing & Sons, we've mastered the art and science of EPDM roofing installation, delivering exceptionally resilient and weather-defiant protection for discerning property owners. Our premium synthetic rubber membrane systems create an impenetrable shield against torrential rainfall, punishing winds, and relentless UV exposure—maintaining their structural integrity for decades while demanding minimal upkeep.

Our master craftsmen execute each EPDM installation with meticulous precision and unwavering attention to detail, creating a seamless barrier that withstands the harshest elements and the unforgiving test of time. We utilize only laboratory-tested, industry-leading materials and adhere rigorously to advanced installation protocols that ensure your roofing system delivers flawless performance in even the most challenging environmental conditions.

Partnering with Superior Roofing means gaining access to seasoned professionals who truly understand that your roof represents the first line of defense for your valuable property. Our hallmarks of crystal-clear communication and streamlined project management transform what could be a complex undertaking into a remarkably smooth, transparent, and worry-free experience from initial consultation through final inspection.

Types of EPDM Roofing Solutions Offered

We provide different methods of EPDM roofing installation to match specific building needs and budgets. Each option has its own benefits in terms of durability, cost, and ease of maintenance.

Fully Adhered EPDM Systems

This method involves gluing the EPDM membrane directly onto the roof deck. We use strong adhesives to create a continuous bond, which helps reduce wind uplift and water penetration.

Fully adhered systems work well on roofs with complex shapes because the membrane molds closely to the surface. This option offers excellent durability and long-term performance. It also provides better fire resistance compared to other methods.

The installation requires careful surface preparation to ensure adhesion. It tends to be more expensive but offers a cleaner look and fewer moving parts, reducing chances of leaks.

Mechanically Attached Systems

Here, the membrane is fastened to the roof deck using special plates and screws. We attach the membrane in overlapping strips to ensure tight seams.

This system balances cost and strength by avoiding adhesives and ballast. It is lighter than ballasted roofs and usually quicker to install than fully adhered systems.

Mechanically attached EPDM works well on roofs with moderate slopes. It allows easy membrane replacement but may be more vulnerable to wind uplift if not installed correctly. We use precise fastening patterns to improve stability and performance.

Ballasted EPDM Systems

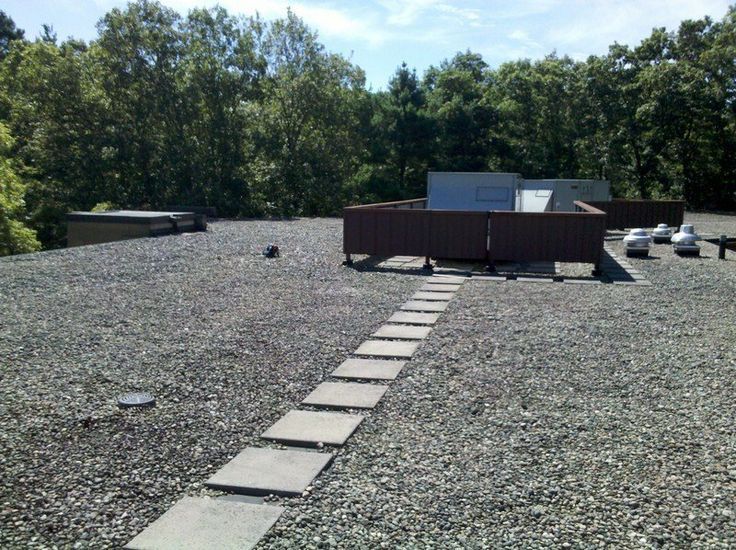

Ballasted systems use heavy materials like gravel or pavers placed on top of the EPDM membrane to keep it in place. We install a loose-laid membrane first, then add the ballast layer.

This method is cost-effective and easier to install on large, flat roofs. It allows quick installation and simple repairs since the membrane is not glued or mechanically attached.

The ballast protects the membrane from UV rays and physical damage. However, it adds extra weight to the roof structure, which must be able to support it. Drainage design is important because ballast can affect water flow.

Our EPDM Maintenance and Repair Services

Maintaining an EPDM roof properly helps extend its life and keeps it functioning well. We focus on regular checkups, fast leak repairs, and advice to protect your roof over time.

Routine Maintenance Programs

We set up scheduled inspections to catch small problems before they get worse. This includes checking seams, flashing, and the rubber membrane for cracks or wear. We remove debris and clean the roof surface to prevent damage from dirt or standing water.

Our maintenance program also involves resealing joints and fixing minor tears. This keeps the roof watertight and prevents leaks. Regular inspections help ensure your EPDM roof stays in good shape through all seasons.

Leak Detection and Emergency Repairs

When leaks happen, time is critical. We use precise tools to find the exact source of water intrusion quickly. This involves testing the roof surface and seams.

After locating the leak, we apply durable patches or replace damaged sections. Our emergency repair team is ready to respond promptly to minimize damage inside your building. We also check surrounding areas to ensure no hidden leaks remain.

Long-Term Protection Recommendations

To keep your EPDM roof performing well for years, we recommend several key actions. These include regular application of protective coatings to resist UV rays and prevent cracking.

We advise installing proper drainage systems to avoid water pooling. Also, avoid foot traffic on the roof except when necessary, and use protective walkways if access is needed. These steps reduce wear and extend your roof’s lifespan.

Why Us

We focus on proven skills, clear communication, and strong protections. Our team brings years of expertise and makes sure clients feel supported throughout every step. We back our work with solid warranties to give peace of mind.

Experience Matters

We have over 20 years of experience installing EPDM roofing. Our team is trained and certified by leading roofing manufacturers. This means we follow the best practices to ensure your roof lasts.

Our technicians undergo ongoing training to keep up with industry standards. We also carry all required licenses and insurance to protect your property. Our past projects include commercial and residential EPDM roofs, giving us the skill to handle any size job.

Customer-Centric

We believe communication is key. From the first call to the final inspection, we keep you informed and involved. We listen to your needs and tailor our work to fit your building and budget.

Our team respects your schedule and works efficiently to minimize disruption. We clean up thoroughly after each job. If you have questions, we respond quickly and clearly. Your satisfaction is our priority every step of the way.

Warranties and Guarantees

We provide strong warranties on all EPDM roofing installations. Our materials come with manufacturer-backed warranties that cover defects and early wear.

On top of that, we offer a workmanship guarantee for up to 10 years. This covers any installation issues that may arise. Documentation is clear, so you understand what is included. These protections help ensure long-term value for your investment.

FAQs on EPDM Roofing Installation

We want to help you understand key details about EPDM roofing. Cost can vary, the life of your roof depends on care, and some projects allow installation over existing roofs. We also cover how to maintain your roof, warranty options, and how weather can impact when we work.

What factors influence the cost of EPDM roofing installation?

The size of your roof is the main cost factor. Materials, roof complexity, and labor also affect pricing. Extra features like insulation or repairs add to the total cost.

What is the lifespan of an EPDM roofing system when installed by professionals?

Our EPDM roofs typically last 20 to 30 years. Proper installation and regular maintenance help reach the upper end of that range.

Can EPDM roofing be installed over an existing roof, and what are the considerations?

EPDM can often be installed over a flat, sound roof. We inspect the old roof for damage first. Proper preparation ensures a strong bond and good performance.

What maintenance is required for EPDM roofs?

We recommend checking the roof twice a year for debris and damage. Cleaning with water and mild soap keeps it in good shape. Avoid walking on it unnecessarily.

How does weather affect the installation schedule for EPDM roofs?

We try to avoid extreme heat or cold because it impacts material performance. Rain or wet conditions also delay installation to ensure proper sealing.